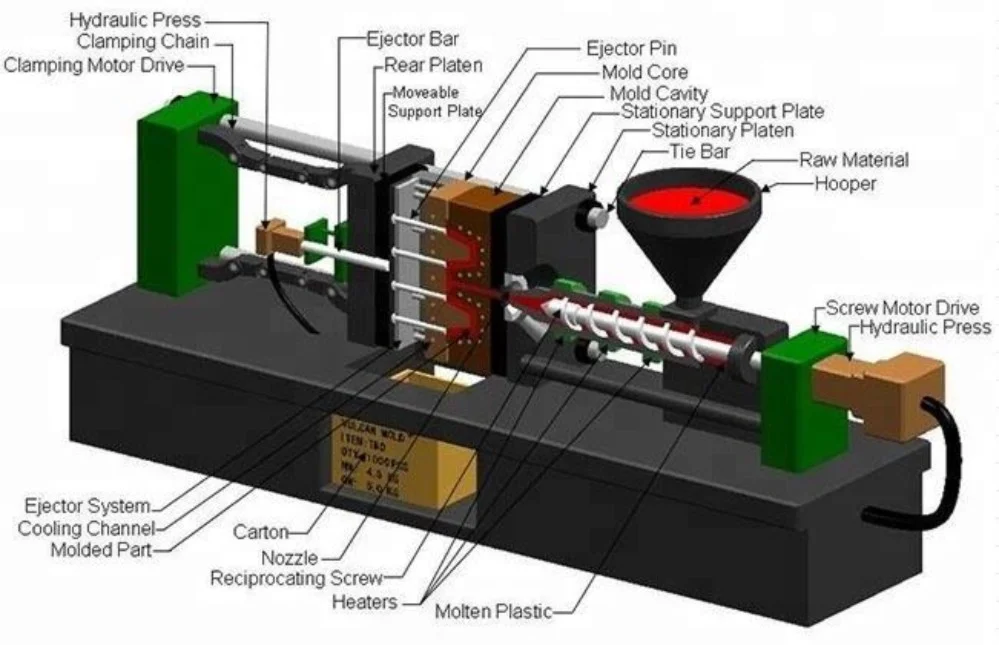

In the intricate world of advanced manufacturing, where precision meets innovation, stainless steel injection molding is an advanced manufacturing technique that utilizes high-pressure injection to force molten stainless steel into intricately designed molds. Changhong Precision, a leading manufacturer in the field of advanced manufacturing, specializes in the production of high-quality stainless steel injection molding components. Leveraging cutting-edge technology and precision engineering, the company ensures that its stainless steel injection molded parts meet the most stringent standards of durability, corrosion resistance, and precision. Changhong Precision's commitment to excellence makes it an ideal partner for industries seeking reliable and robust stainless steel solutions.

The Science Behind Stainless Steel Injection Molding

Stainless steel injection molding is a sophisticated process that combines the durability of stainless steel with the precision and scalability of injection molding techniques. Traditionally, stainless steel was reserved for applications requiring extreme corrosion resistance and strength, often fabricated through methods like casting or machining. However, injection molding offers a groundbreaking alternative, enabling the production of complex, intricate parts with tight tolerances and consistent quality.

At Changhong Precision, the process begins with meticulous material selection. Stainless steel grades, such as 304 and 316, are chosen based on their specific properties like corrosion resistance, mechanical strength, and weldability. These materials undergo rigorous purification and compounding processes to ensure optimal flow characteristics during molding.

Changhong Precision: Pioneering Innovation

What sets Changhong Precision apart is its cutting-edge technology and unwavering commitment to excellence. The company's state-of-the-art facilities are equipped with advanced injection molding machines capable of handling the high pressures and temperatures required for stainless steel processing. These machines feature precision temperature control systems and high-performance screws designed specifically for handling the viscosity and abrasiveness of stainless steel melts.

Moreover, Changhong Precision's R&D team continuously experiments with new alloys and molding techniques to push the boundaries of what's possible. Their focus on innovation has led to the development of specialized molds and tooling that can withstand the rigorous demands of stainless steel injection molding, ensuring longer mold life and reduced downtime.

Industry Applications

The versatility of stainless steel injection molding, coupled with Changhong Precision's expertise, has opened up a myriad of applications across diverse industries:

Medical Devices: The need for sterile, corrosion-resistant components in medical equipment makes stainless steel injection molding ideal. From surgical instruments to implantable devices, Changhong Precision ensures precision and reliability.

Automotive Industry: In the automotive sector, stainless steel parts are crucial for components exposed to harsh environments, such as exhaust systems and fuel injection components. Changhong Precision's ability to produce complex geometries with consistent quality enhances performance and reduces weight.

Food & Beverage: Hygiene and durability are paramount in food processing equipment. Stainless steel injection molded parts, such as valves, fittings, and conveyors, meet these criteria while optimizing production efficiency.

Aerospace: In the aerospace industry, where lightweight strength and corrosion resistance are critical, Changhong Precision's stainless steel injection molding technology delivers precision components for engines, landing gear, and other critical systems.

Sustainability and Efficiency: Changhong Precision's Commitment

Beyond technical prowess, Changhong Precision is also at the forefront of sustainable manufacturing practices. By optimizing material usage and reducing waste through precise molding techniques, the company contributes to a more environmentally conscious production process. Additionally, the use of stainless steel, known for its recyclability, aligns with the growing trend towards circular economy principles.

Conclusion

As industries continue to evolve and demand for high-performance, precision-engineered components grows, Changhong Precision stands as a testament to the power of innovation in stainless steel injection molding. Their dedication to mastering this advanced manufacturing technique not only propels forward-thinking companies but also sets new standards for quality, efficiency, and sustainability.

In a world where the fusion of technology and material science is driving progress, Changhong Precision's mastery in stainless steel injection molding serves as an inspiring example of how the future of manufacturing is being shaped today. From medical breakthroughs to automotive advancements, the impact of their work is felt far and wide, heralding a new era of precision and innovation.