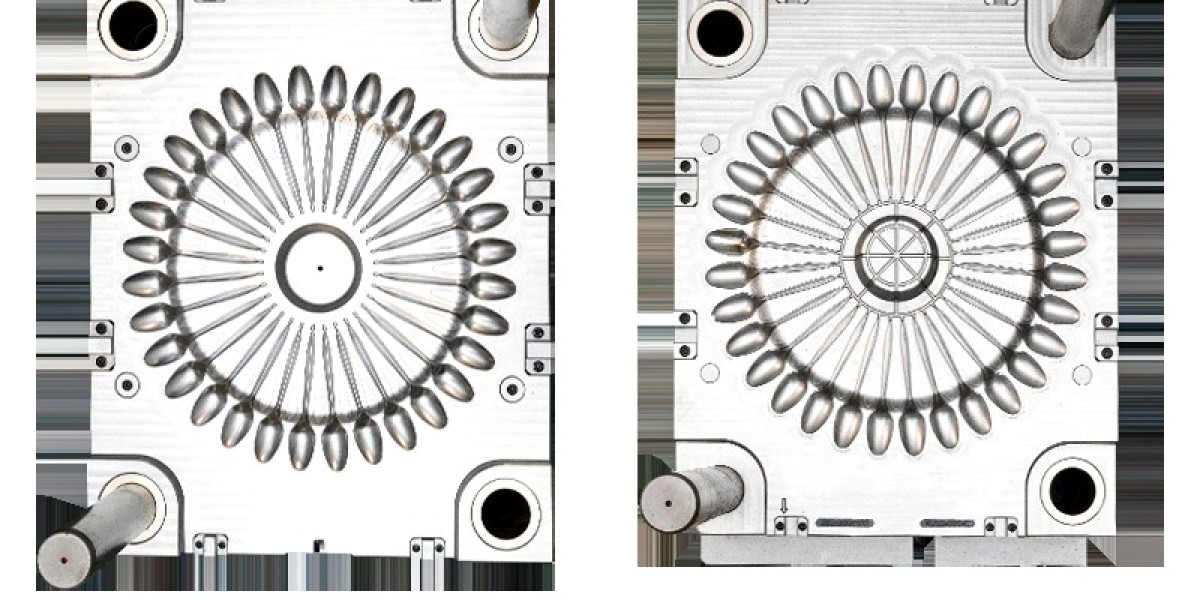

The mass production of disposable cutlery depends fundamentally on the precision and efficiency of the plastic fork mould, a highly specialized tool used in injection molding manufacturing. This engineered component is responsible for forming molten plastic into functional fork shapes with consistent tine spacing, handle ergonomics, and structural integrity. The design and construction of a plastic fork mould require sophisticated engineering knowledge and precise machining capabilities to create cavities that will produce identical utensils at high production rates. The quality of the final plastic fork is directly determined by the accuracy and finish of the plastic fork mould, making it an essential element in the manufacturing process for disposable cutlery used in food service, catering, and packaging industries globally.

The creation of a plastic fork mould begins with comprehensive design specifications that address the utensil's functional requirements, including tine strength, handle comfort, and stacking capability. Mold designers utilize computer-aided design software to develop detailed 3D models of the mold cavities, cores, and ejection systems. The physical plastic fork mould is typically fabricated from hardened tool steel or beryllium-free copper alloys, with material selection based on production volume expectations and thermal conductivity requirements. Precision machining centers mill the negative impression of the fork design into the mold blocks with extremely tight tolerances to ensure consistent product quality. The plastic fork mould incorporates various components including guide pillars, ejector pins, cooling channels, and venting systems to facilitate efficient production cycles and prevent manufacturing defects in the finished utensils.

The operation of a plastic fork mould involves a carefully controlled injection molding process where thermoplastic material is heated to liquid state and injected under pressure into the mold cavity. The design includes complex cooling channels that circulate temperature-controlled fluid to solidify the plastic quickly before mold opening and part ejection. Cycle time—the duration required for injection, cooling, and ejection—is significantly influenced by the thermal management efficiency of the plastic fork mould. Regular maintenance is crucial for prolonged service life, including cleaning of resin residues, inspection of moving components, and polishing of cavity surfaces to maintain product quality. The continuous advancement in plastic fork mould technology enables manufacturers to produce increasingly sophisticated utensil designs with improved functionality and production efficiency.