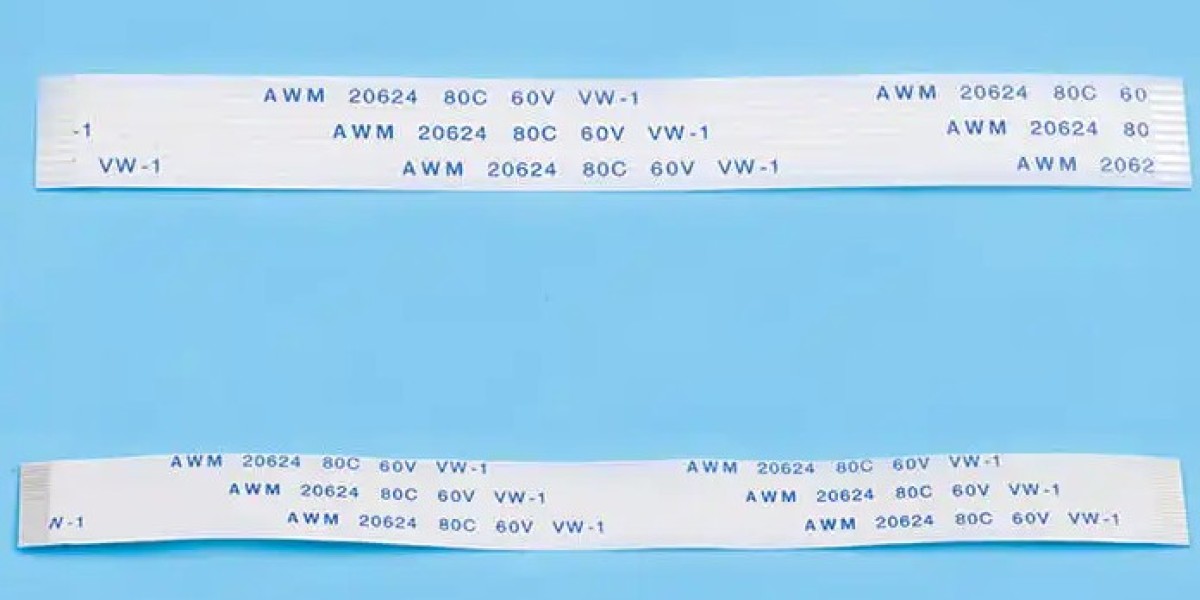

When integrating electronic components, the mechanical properties of FFC Ribbon Cable play a critical role in both installation and long-term performance. Flexibility and tensile strength are particularly important factors that determine how easily the cable can be routed, connected, and maintained within devices. Proper understanding of these characteristics allows engineers and technicians to achieve reliable connections while minimizing the risk of damage during installation or operation.

Flexibility is one of the most significant attributes of FFC Ribbon Cables. These cables are designed to bend, fold, and curve to accommodate compact layouts and complex pathways within electronic devices. High flexibility allows the cable to conform to tight spaces, follow intricate routing paths, and adjust to movement between components without putting stress on the connectors or solder joints. In applications such as laptops, smartphones, and other portable devices, where space is limited, a highly flexible ribbon cable ensures that the device can be assembled efficiently and maintain optimal performance even when subjected to repeated handling or movement.

Tensile strength, or the resistance of the cable to pulling forces, is equally crucial. During installation, connectors are often inserted or removed multiple times, and the cable may be subjected to tension while being positioned. Adequate tensile strength ensures that the cable does not stretch, tear, or delaminate under these mechanical stresses. It also prevents damage to the conductive traces inside the cable, which could otherwise lead to intermittent connections or total failure. Balancing flexibility with sufficient pull resistance is therefore essential for both reliability and safety.

The interaction between flexibility and tensile strength directly impacts long-term usage. Cables that are too rigid may be difficult to install in compact systems and are prone to cracking or breaking when bent repeatedly. Conversely, overly soft cables without adequate tensile strength may deform under load, causing misalignment with connectors and potential signal interruptions. High-quality FFC Ribbon Cables are engineered to provide both properties in balance, enabling efficient assembly, secure connections, and reliable operation over the device’s lifetime.

Environmental factors, such as temperature fluctuations and mechanical vibration, can further influence performance. Flexible cables with high tensile strength are better equipped to withstand thermal expansion, contraction, and vibration without suffering permanent deformation or internal damage. This characteristic is especially important in automotive, industrial, and high-performance electronic applications where cables are exposed to dynamic conditions.

In conclusion, the flexibility and tensile strength of FFC Ribbon Cable are key determinants of both installation ease and long-term reliability. Flexibility allows for routing in compact or complex systems, while tensile strength ensures resistance to pulling forces and mechanical stress. Selecting a cable with the appropriate balance of these properties is essential to maintain secure electrical connections, reduce installation difficulties, and ensure stable performance in a wide range of electronic devices and applications. Proper understanding of these mechanical characteristics enables engineers to design systems that are both efficient and durable, avoiding premature failures and enhancing the overall quality of the product.

Flexible flat cable FFC ribbon cable 0.5mm pitch - flexible ribbon wire cable, high-speed data transfer, flexible and durable.