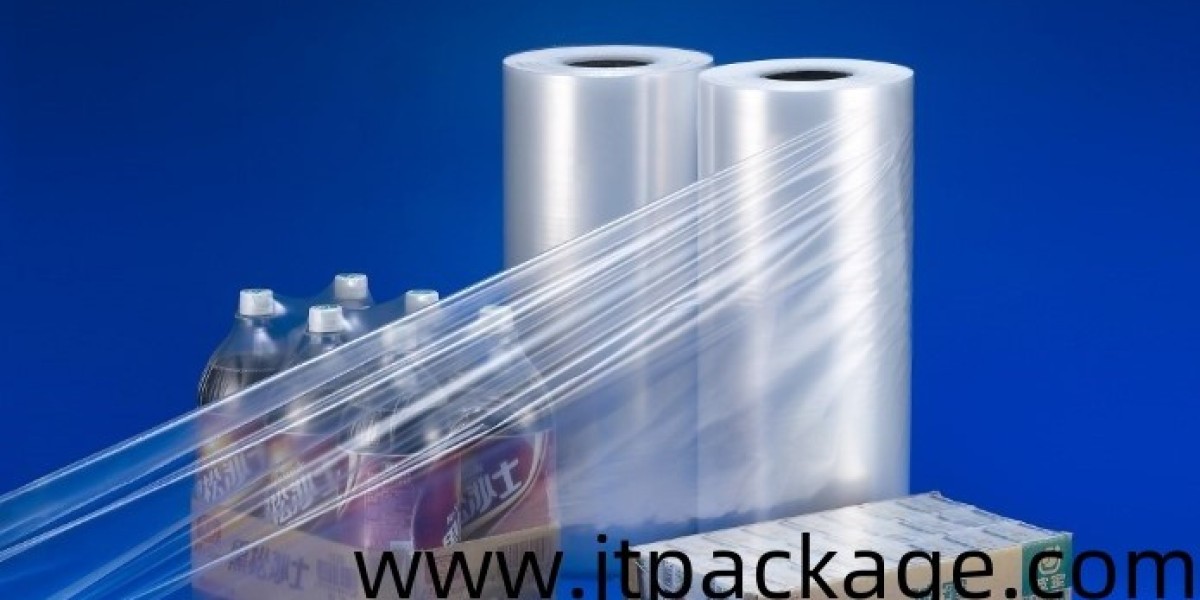

In industries where packaging must withstand extreme conditions, Crosslinked Shrink Film has become the gold standard. This advanced material undergoes a specialized chemical process to create interlinked polymer chains, resulting in unparalleled strength and thermal stability. From automotive parts to heavy machinery, crosslinked shrink film ensures products arrive intact, even in the harshest environments.

The science behind crosslinked shrink film lies in its molecular structure. During manufacturing, electron beam or chemical treatments create covalent bonds between polymer chains. This three-dimensional network enhances resistance to punctures, tears, and high temperatures—up to 120°C in some applications. A leading aerospace supplier reported that switching to crosslinked film eliminated packaging failures during transcontinental air freight, where cargo holds experience rapid pressure changes.

Unlike non-crosslinked variants, this film maintains dimensional stability during shrinking, preventing wrinkles or uneven seals. This precision is critical for industries like medical device manufacturing. For example, a German surgical tool producer uses our crosslinked film to package sterilized instruments. The film's ability to form a hermetic seal without loosening ensures compliance with ISO 11607 standards for sterile barrier systems.

JTPackage's crosslinked shrink film excels in high-speed packaging lines. A beverage conglomerate achieved a 22% increase in production speed after adopting our film, thanks to its consistent shrinkage behavior across varying conveyor temperatures. Our films are available in thicknesses from 15μm to 30μm, catering to applications as diverse as bundling construction materials and protecting agricultural machinery components.

Sustainability remains a priority. Our Crosslinked Film variants are compatible with existing recycling streams, and we offer a take-back program for industrial clients. A case study with a Nordic furniture brand showed that combining our film with reusable pallet covers reduced their annual plastic consumption by 18 metric tons.

Discover industrial-grade solutions: https://www.jtpackage.com