In today's competitive market, businesses are constantly seeking innovative solutions to meet the diverse needs of their customers. At Changhong Precision, we specialize in providing custom injection molding services that cater to a wide range of industries. Our expertise and commitment to excellence ensure that we deliver high-quality, precision-molded parts that meet or exceed your expectations.

Materials Service: Versatility and Quality

When it comes to injection molding, the choice of materials is crucial. At Changhong, we offer a wide range of plastic materials to suit your specific needs. From common thermoplastics like polypropylene and polyethylene to engineering plastics such as nylon and polycarbonate, we have many plastic materials available to meet your diverse requirements.

Wide Range of Materials

Our materials service is designed to provide you with the flexibility you need to create the perfect product. Whether you're developing automotive parts, household commodities, medical products, or consumer electronics, we have the right material for your application. Our extensive inventory of plastics includes:

Thermoplastics: These materials are easy to process and offer good mechanical properties, making them ideal for a wide range of applications.

Engineering Plastics: These high-performance plastics are known for their strength, durability, and resistance to heat and chemicals.

Specialty Plastics: For unique applications, we also offer specialty plastics that provide specific properties such as flame retardancy, electrical conductivity, or biocompatibility.

Custom Material Solutions

In addition to our standard materials, we also offer custom material solutions. If you have a specific requirement that isn't met by our standard offerings, our team of experts can work with you to develop a custom plastic compound that meets your needs. This includes modifying existing materials or creating entirely new formulations to achieve the desired properties.

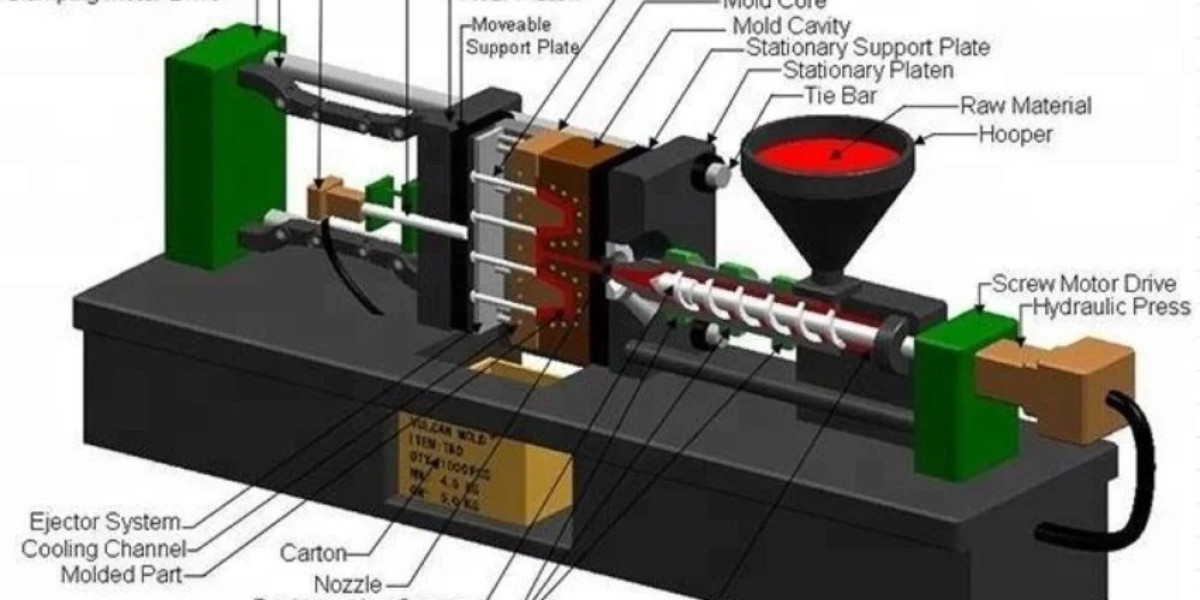

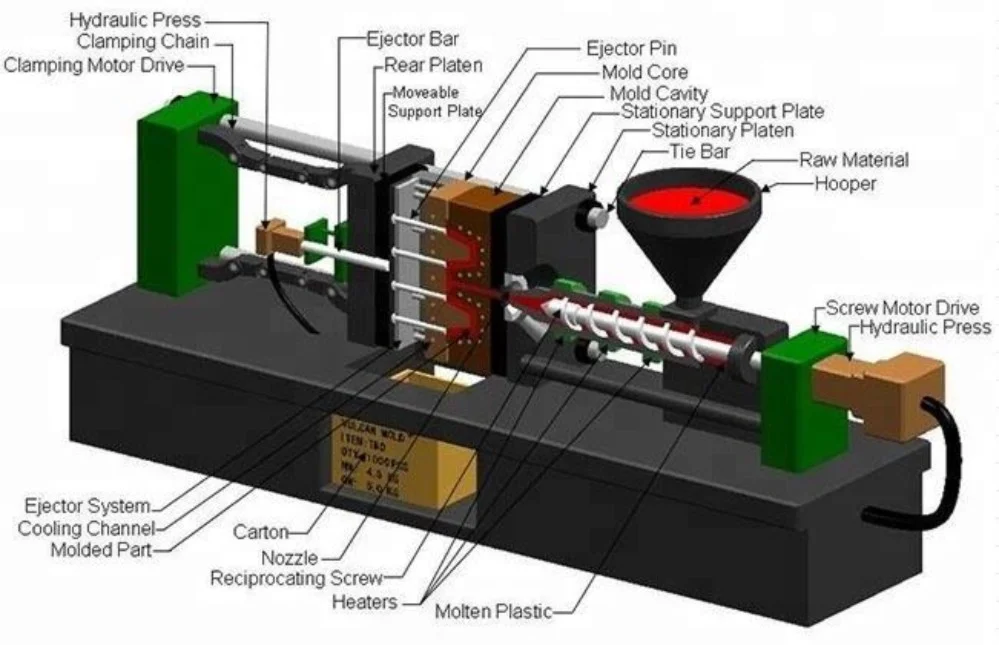

Precision Manufacturing and Design

At Changhong, we understand that precision is key to successful injection molding. Our state-of-the-art facilities and advanced manufacturing techniques ensure that we deliver parts with consistent quality and tight tolerances.

Design Expertise

Our design team has extensive experience in creating injection molds for a wide range of applications. From simple geometries to complex assemblies, we have the expertise to design a mold that will produce parts that meet your specifications. We use the latest CAD/CAM software to create precise 3D models of your parts, allowing us to optimize the mold design for efficient production and minimal waste.

Manufacturing Capabilities

Our manufacturing capabilities are second to none. We utilize high-precision machining equipment to create molds with intricate details and tight tolerances. Our injection molding machines are capable of producing parts in a wide range of sizes and quantities, from prototype runs to full-scale production.

Diverse Applications

The versatility of our materials and manufacturing capabilities allows us to serve a wide range of industries. Here are just a few examples of the types of parts we can produce:

Automotive Parts: From interior trim components to engine components, we have the expertise to produce high-quality automotive parts.

Home Applications: From kitchenware to furniture, we can create custom injection molded parts for a wide range of home applications.

Medical Products: Our precision manufacturing capabilities make us an ideal partner for producing medical devices and components.

Household Commodities: From storage containers to tool handles, we can produce a wide range of household items.

Consumer Electronics: From phone cases to computer components, we have the experience to create custom injection molded parts for consumer electronics.

Mobile Phone Parts and Accessories: Our precision and quality control make us a trusted partner for producing mobile phone parts and accessories.

Quality Assurance and Customer Support

At Changhong, we take quality assurance seriously. Our rigorous testing protocols and quality control measures ensure that every part we produce meets or exceeds your specifications. We also offer comprehensive customer support, from initial design consultations to after-sales service.

Testing and Quality Control

Our quality control team performs a range of tests on every batch of parts we produce. This includes dimensional inspections, material testing, and functional testing to ensure that the parts meet your requirements. We also maintain a comprehensive traceability system to track every part from raw material to final product.

Customer Support

Our customer support team is dedicated to providing you with the best possible service. We offer design consultations to help you optimize your part design for injection molding, as well as ongoing support throughout the production process. If you have any questions or concerns, our team is always available to assist you.

In conclusion, Changhong custom injection molding services offers a wide range of materials, precision manufacturing capabilities, and diverse applications to meet your diverse needs. Our commitment to quality and customer support ensures that you'll receive the best possible service and products. Contact us today to learn more about how we can help you with your custom injection molding project.